The main types of carpet are:

Tufted

The tufting process is similar to the action of a regular sewing machine. A cloth (called primary backing) is passed underneath a long bar containing hundreds of individual needles carrying the carpet yarn through the eye. The needles insert yarn into the backing cloth, the needles withdraw and a small hook holds the yarn to form a loop on the underside of the cloth which will become the ‘use’ surface of the carpet. The result is loop pile carpet. When cut pile carpet is required, the hook that holds the yarn is fitted with a blade that cuts the top of the loop, which forms two legs of yarn, or a cut pile surface. The tufted cloth (whether loop or cut pile) then has synthetic latex (an adhesive) applied to the primary backing and a secondary backing fabric is then attached to stabilize the carpet and give it the final form.

Modular (Tiles)

Modular carpet or carpet tiles are produced by inserting tufts into a PVC or bitumen compound which has been coated onto a backing fabric. Modular carpet is produced mainly for the contract market.

Woven

This is the traditional method of making carpet and the process dates back over 200 years. Woven carpet is sometimes referred to Axminster or Wilton. These are the types of weaving looms. Compared to tufting, woven carpet manufacturing is slower and more labour intensive. Consequently woven carpet tends to be more expensive than tufted carpet, but with unlimited designs and 200 years of performance, woven carpet is still very popular in some market segments (e.g. prestige installations and period homes where intricate patterns, custom design work and durability are particularly important).

There are two basic carpet constructions: cut pile and loop pile. They can also be combined in one surface design to create a cut and loop construction. These constructions can also produce a vast range of different surface effects that are known as styles:

Cut pile styles

Cut pile styles include Velvet, Plush, Saxony, Hard Twist / Frieze, Shag, Twist, Heather Twist.

Cut pile

There are different classifications of cut pile carpets, and these refer mainly to the twist level of the pile yarn and description of the pile length.

Velvet

Both velour and velvet have a short pile length. The loop lines can be either uniform in height or a sequence of alternating low and high loop rows. Velvet yarn has very little twist and may not be heat set. The pile tufts are burst similar to a velour but velvet has a slightly longer pile length.

Saxony

Another popoular cut-pile sytle, a saxony has a relatively high pile and the end of the tuft flairs slightly to produce a luxurious smooth surface. ‘Plush’ or ‘velvet’ cut pile constructions are similar to the saxony but have a lower pile height and tighter tuft definition (with little to no ‘tip flair’).

Plush

Plush is also a level-cut pile. The yarn has a little more twist than a velvet pile carpet, and is usually set to retain this twist (water, steam, dye or chemical setting are used to set wool yarns).

Cut and Loop

Also known as carved or sculptured pile, it is basically a cut pile carpet with areas of loop pile designed into it.

Hard Twist

The hard twist style is also known as Frieze (pronounced ‘freezay’) or curled pile. A cut pile style with a ‘textured’ finish made up of highly twisted tufts that curl slightly at the pile surface. The yarn is tightly twisted then heat set to give a textured look to the pile surface. The pile appears to lay randomly.

Shag

The pile tufts are very long and create a low density construction, because the spacing of the tufts is more open than other carpet constructions.

| Cut Pile Style Descriptions | Pile Length Description | Pile Length (mm) |

| Shag | Long | ? 20 |

| Semi Shag (Splush) | Medium to Long | ? 20 |

| Plush | Medium | ? 15 |

| Saxony | Medium | ? 15 |

| Velour | Short to Medium | ? 12 |

| Velvet | Short | ? 10 |

Some styles are more functional than others, so consider where the carpet will be laid – in a heavy traffic area like the family room or a hallway, or in a lighter traffic area such as a dining room or spare bedroom.

Also think about the ambience of the room. Are you creating a contemporary space, a formal look or something cosy or functional?

Talk to your retailer about the décor effects you are trying to achieve, and the likely traffic levels. They will assist you in selecting the best style for your home.

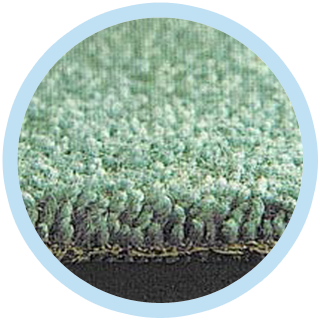

Loop Pile Styles

Loop pile styles include Level Loop, Sisal, Cord, Multilevel Loop, Textured Loop.

Level Loop

A simple loop pile with tufts of equal height normally in a ‘tight’ construction using fairly fine yarn.

Berber, Heather, Tweed

Normally made of thicker yarns tufted into chunky loop tufts and usually of earth tones with a flecked or mottled appearance. Berbers can also be produced in a cut pile construction.

Sisal / Cord

These names are used inter-changeably but they generally refer to a heavily textured loop pile carpet. A sisal/cord carpet has a similar look to the traditional mat floor coverings made from plant fibres, but in carpet, it is a much more stylish and comfortable alternative. The loop lines can be either uniform height or a sequence of alternating low and high lines.

Multi-Level Loop

This is also referred to as high-low loop or sculptured loop. As these names imply, this carpet is made up of different pile heights, two or three heights being the most common. The difference in height creates a surface that can be described as sculptured, with the pattern appearing to have been carved from the carpet.

In Australia, the three major fibres used in carpets are nylon (polyamide), wool and polypropylene (polyolefin). Some carpets are made of blends e.g. 80% wool with 20% nylon is a common blend.

Despite the competing claims of fibre suppliers, no one fibre necessarily makes a better carpet. Good carpets are made from good raw materials and components, coupled with the skills of the manufacturer to produce a properly constructed carpet using these components.

For this reason, there is no simple answer to the ‘which fibre is best’ question and it is unwise for consumers to base a buying decision on fibre alone.

The Australian Carpet Classification Scheme (ACCS) helps to take the guesswork out of the carpet selection process. The best advice is to use the ACCS to isolate the performance level you want and then let your personal preferences rule your decision on fibre, colour, texture, feel and style.

Further information

Click here to find more information from a carpet Manufacturer, Retailer or Product & Service Suppliers

- Fact sheet

Carpet Styles

Download this PDF document

Find a Store that is a Carpet Institute member or that stocks carpet and underlay from an Institute member.